- TOP

- Case Study/Service Search

- Review of Production Distribution

Physical Distribution within Factory

From manufacturing stages, starting with the acquisition of raw materials to the control of storage and line production, Shinozaki Transportation makes use of years of distribution know-how, allowing our customers to focus on their core business. Our track record of delivering value to manufacturers has proven our capabilities in the steel, paper, pulp, poly, and building materials industries for domestics and overseas markets.

Poly Manufactured Products, Distribution (example)

Raw materials, components, and goods are received from various suppliers stored in our warehouse and distributed according to line production scheduling.

Order is placed for customer, for replenishment of raw materials necessary for production.

Depending on the product, kitting and packing are performed for each finished product and stored in our warehouse.

To each corresponding order, exported via container, the process of picking, packing (including mixed loading) is prepared for charter or shipment.

Support for packing, kitting etcetera

To take hold of other coherent value added services in the production lines, Shinozaki Transportation imparts the service of filling, packaging, instruction on manual bundling, etcetera, as an essential part of our production distribution support.

Or As an essential part of production distribution support, Shinozaki Transportation provides filling, packaging, and instruction on manual bundling, etcetera.

Our business acumen, based on our continuous efforts of quality improvement is measured by a low incidence of defective delivery and the voice of our customers.

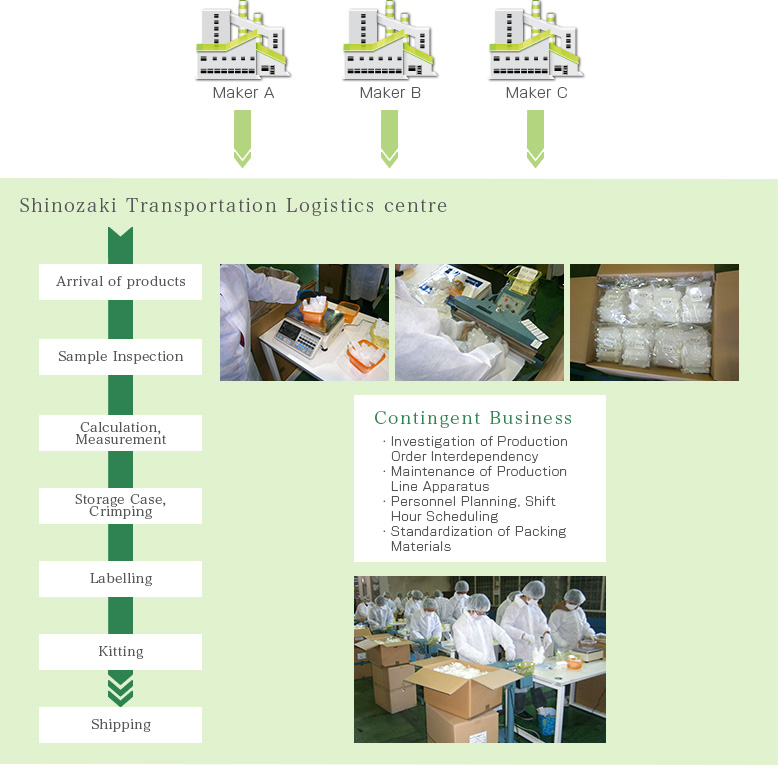

Parts Maker (example)

After inspection of sample parts for large lot orders from a sub-contractor is packaged and labelled for shipment, procedures for kitting and production distribution are planned for multiple destinations throughout the country.

To achieve a stable and standardized productivity level and minimize non-value added work, the time required to complete process is constantly recorded (stop watch) and measured to attain optimal working efficiencies.